| Product Name | |

| Material | api 5ct J55 K55 N80 L80 API 5L x42 x52 x60 x70 ; H40 C95 N80I N80 Q C-90 T-95 P110 Q-125 |

| Size | Size 1.050" to 20" Outside Diameter 26.67 mm to 508 mm |

| Standard | API5L , API 5CT API 5DP |

| Certificates | API5L, API 5L ISO 9001:2008,SGS, BV,CCIC |

| Wall thickness | 2.87~16.13 MM |

| Surface Treatment | black paint, varnish, oil, galvanized, anti corrosion coatings |

| End Type | LTC STC EUE NUE VAM XC NPT |

| Pipe Ends | Under 2 inch plain end. 2 inch and above Beveled. Plastic caps (small OD) ,Iron protector (large OD) |

| Pipe Length | 1. R1: 4.88~7.62M. 2. R2:7.62~10.36M 3.R3:10.36~14.63M |

| Packaging | Loose package; Packaged in bundles(2Ton Max); bundled pipes with two slings at the both end for easy loading and discharging; End with Plastic caps; wooden cases. |

| Test | Chemical Component Analysis, Mechanical Properties, Technical Properties, Exterior Size Inspection, hydraulic testing , X-ray Test. |

| Application | oil pipe; gas pipe DRILL |

| Advantages | 1.Reasonable price with excellent quality 2.Abundant stock and prompt delivery 3.Rich supply and export experience, sincere service 4.Reliable forwarder, 2-hour away from port. |

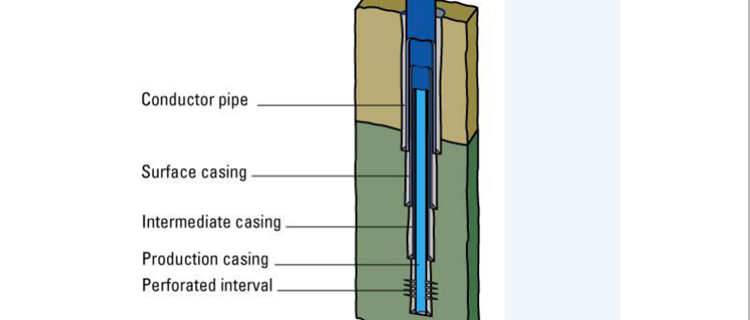

How Does Casing Work?

Once a well has been drilled, if it is to become a production well, the well must undergo completion. While drilling a well cuts through the rock formations and allows drilling engineers to reach the reservoir below, the raw sides of the well cannot support themselves. Similar to the bones of your spine protecting the spinal cord, casing is tubing that is set inside the drilled well to protect and support the wellstream. In addition to providing stabilization and keeping the sides of the well from caving in on themselves, casing protects the wellstream from outside contaminants, as well as any fresh water reservoirs from the oil or gas that is being produced. Also known as setting pipe, casing a well involves running steel pipe down the inside of a recently drilled well. The small space between the casing and the untreated sides of the well is filled with cement to permanently set the casing in place.

Casing A Well.

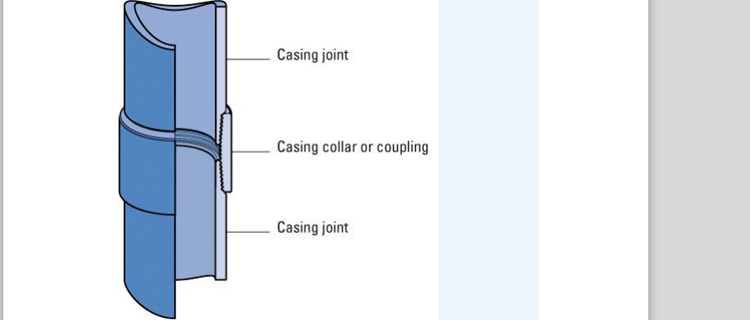

The casing is fabricated in sections, or joints, that are usually about 40 feet long and screwed together to form longer lengths of casing, called casing strings. Each end of the casing joint has male threads that are protected by cap called a thread protector until the casings are ready to be jointed. Then, a collar or coupling, composed of a short cylindrical steel pipe that is slightly larger in diameter than the joints and also has female threads, is used to connect the two male joint ends. A thread compound is used on the two ends to ensure a tight seal. Casing is run from the rig floor, connected one joint at a time by casing elevators on the traveling block and stabbed into the previous casing string that has been inserted into the well. Hanging above the drill floor, casing tongs screw each casing joint to the casing string. Casing is run into the well and officially landed when the weight of the casing string is transferred to the casing hangers, which are located at the top of the well and use slips or threads to suspend the casing in the well. A rounded section of pipe with an open hole on the end, a guide shoe is connected to the first casing string to guide the casing crew in running the casing into the well. Additionally, the outside of the casing has spring-like centralizers attached to them to help position in casing string in the center of the well. After running the casing and before the cementing the well, a used drill bit is inserted into the well via a drillstring, and drilling fluid is then circulated for a certain amount of time to remove any remaining cuttings from the well. Also wall scratchers are dispatched into the well to remove any filter cake that may have formed on the sides of the well. A cement slurry is then pumped into the well and allowed to harden to permanently fix the casing in place. After the cement has hardened, the bottom of the well is drilled out, and the completion process continues.

Shandong Jute Steel Pipe Co.,Ltd. Contacts: Mr. Ji WhatsApp: +86 18865211873 WeChat: +86 18865211873 E-mail: jutesteelpipe@gmail.com E-mail: juteguanye@aliyun.com

Shandong Jute Steel Pipe Co.,Ltd. Contacts: Mr. Ji WhatsApp: +86 18865211873 WeChat: +86 18865211873 E-mail: jutesteelpipe@gmail.com E-mail: juteguanye@aliyun.com